Individual Stickers, Professionally Printed

Die cut stickers are made by slicing through both the sticker and its backing paper, resulting in individual stickers with no excess paper surrounding them (unlike kiss-cut sticker sheets or stickers on rolls). Our cutters can follow detailed design contours, creating custom shaped pieces that look more polished and seamless than general rectangular or circular stickers, especially once applied.

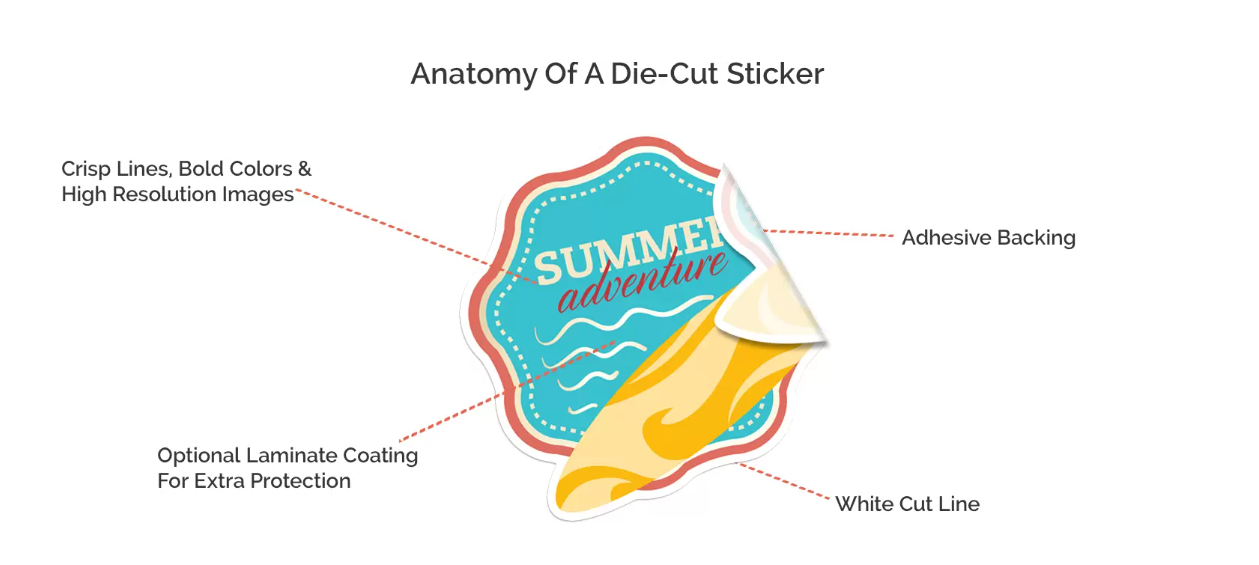

Diagram showing the anatomy of a die-cut sticker, including printed artwork, white cut line, optional laminate coating, adhesive backing, and release liner.

Printed in the UK, these bespoke stickers are available on your choice of paper (in gloss, matt or martele textured) or polypropylene (PP) plastic (in white, clear or metallic). Our paper materials are cheaper and more environmentally friendly, while our PP materials are water resistant, more durable, and offer more variety in design options.

You can also add matt or gloss lamination to your PP die cut vinyl stickers after printing, which will make them more durable still. Laminated PP stickers are completely waterproof, scratch resistant, UV resistant and can be expected to last multiple years. That’s right: your recipients will be able to use their custom shaped stickers on just about anything, from laptops to suitcases to the outside of their cars.

Get Your Logo Seen Everywhere

Our die cut stickers work as a versatile promotional tool for brands and businesses, as well as a sellable artistic commodity.

As a promotional tool, these stickers can be handed out at events or sent as giveaways in customer order packages. Unlike flyers and business cards, our die cut stickers are both self-adhesive and comparatively durable. Customers can, therefore, stick them on mobile phones, laptops, water bottles and other possessions without worrying about sticker damage or peeling. This effectively turns customers into moving billboards for your business, which is another big win.

Printed die cut stickers are also a relatively cheap way for people to enjoy their favourite artists’ work (compared to shirts, mugs, prints, etc.). Fans of your work can personalise their everyday items with individual custom cut stickers of your art, thereby expressing themselves while showing off your art wherever they go.

With their custom shapes and durability, cut out stickers can be utilised in a wide variety of ways by businesses, artists, customers and fans alike.

Die Cut Sticker Features

Adhesive

Die cut stickers can be backed with either permanent or removable adhesive. For most applications a permanent adhesive works best, as it ensures your label will stay stuck on most surfaces. If, however, you are after stickers that can eventually be peeled off cleanly, our temporary adhesive would be the better choice.

Material Thickness

All six sticker materials have different thicknesses, and adding lamination adds a little extra on top of that:

- White PP: 123µm (147µm with gloss lamination; 161µm with matt lamination)

- Clear PP: 116µm (140µm with gloss lamination; 154µm with matt lamination)

- Metallic PP: 113µm (137µm with gloss lamination; 151µm with matt lamination)

- Gloss Paper: 124µm (lamination not recommended)

- Matt Paper: 123µm (lamination not recommended)

- Textured Paper: 195µm (lamination not recommended)

Operating Temperature Range

Our die cut stickers and labels work well in temperatures from -30°C to 80°C. This means they can be put in freezers or applied on the outside of thermos containers without peeling off.

Eco-Friendliness

All of our die cut sticker materials can be recycled, and our paper materials are made from FSC-certified pulp. To recycle them effectively, stickers must be either removed from their surfaces or stuck to surfaces made from similar materials (paper and cardboard for paper materials; polypropylene plastic for PP materials).

Die cut stickers are a fun and versatile way for your customers to further engage with you and/or your brand. To place an order, you can either fill in our online form or get in contact with our Sales Team.